Neural co-optimization of structural topology, manufacturable layers, and path orientations for fiber-reinforced composites

Published in ACM Transactions on Graphics (TOG), 2025

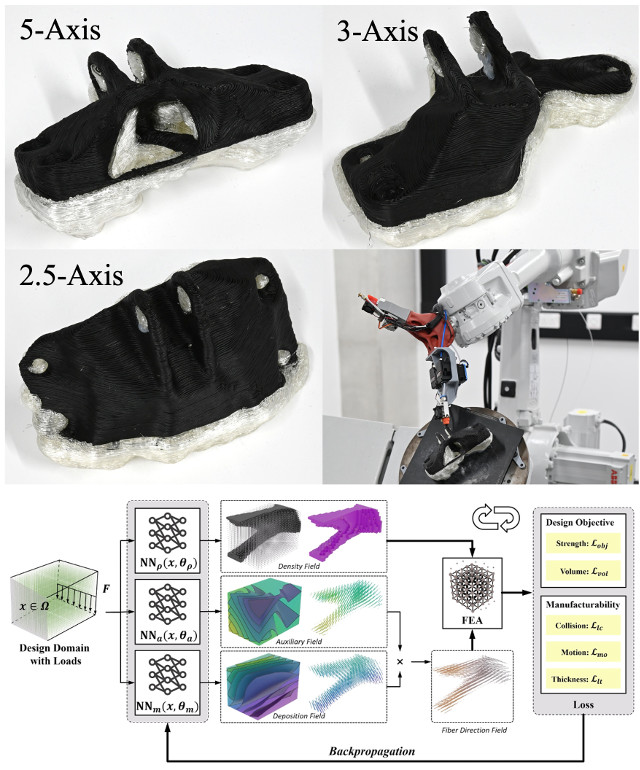

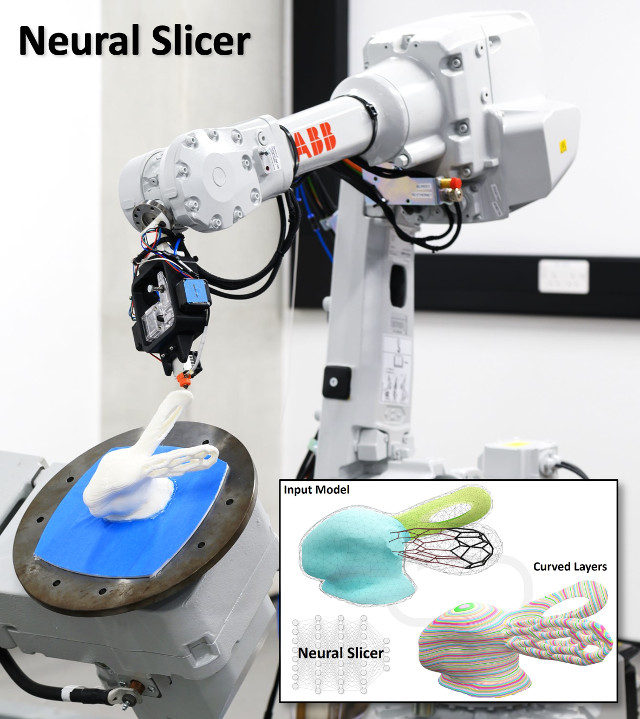

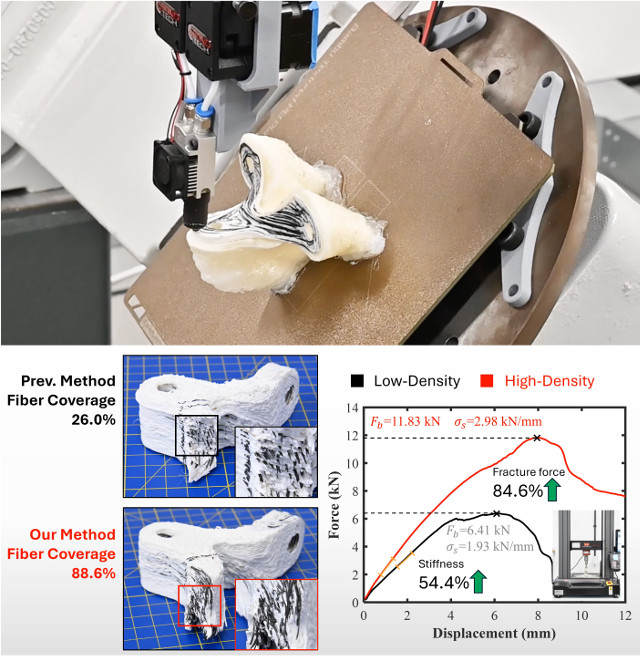

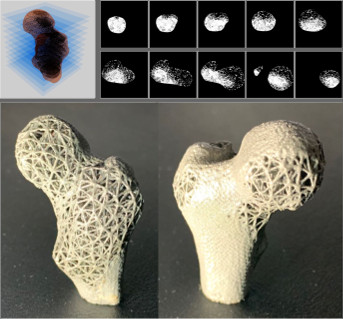

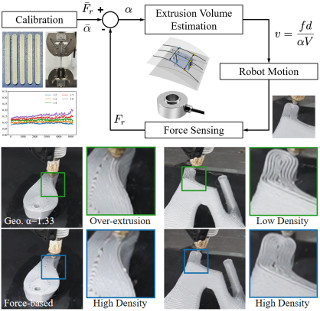

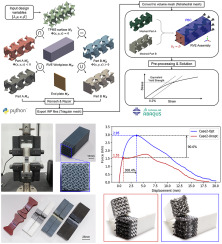

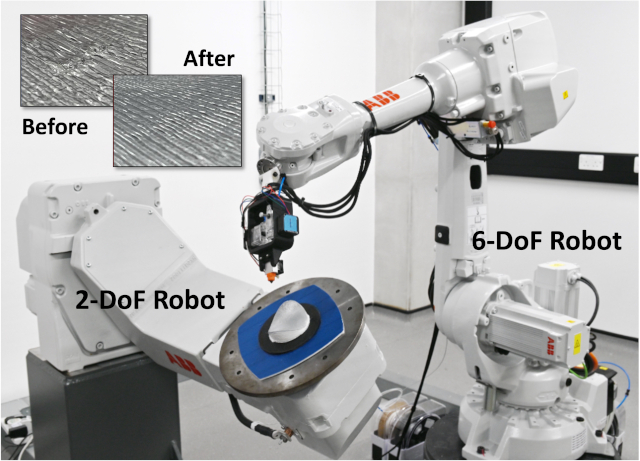

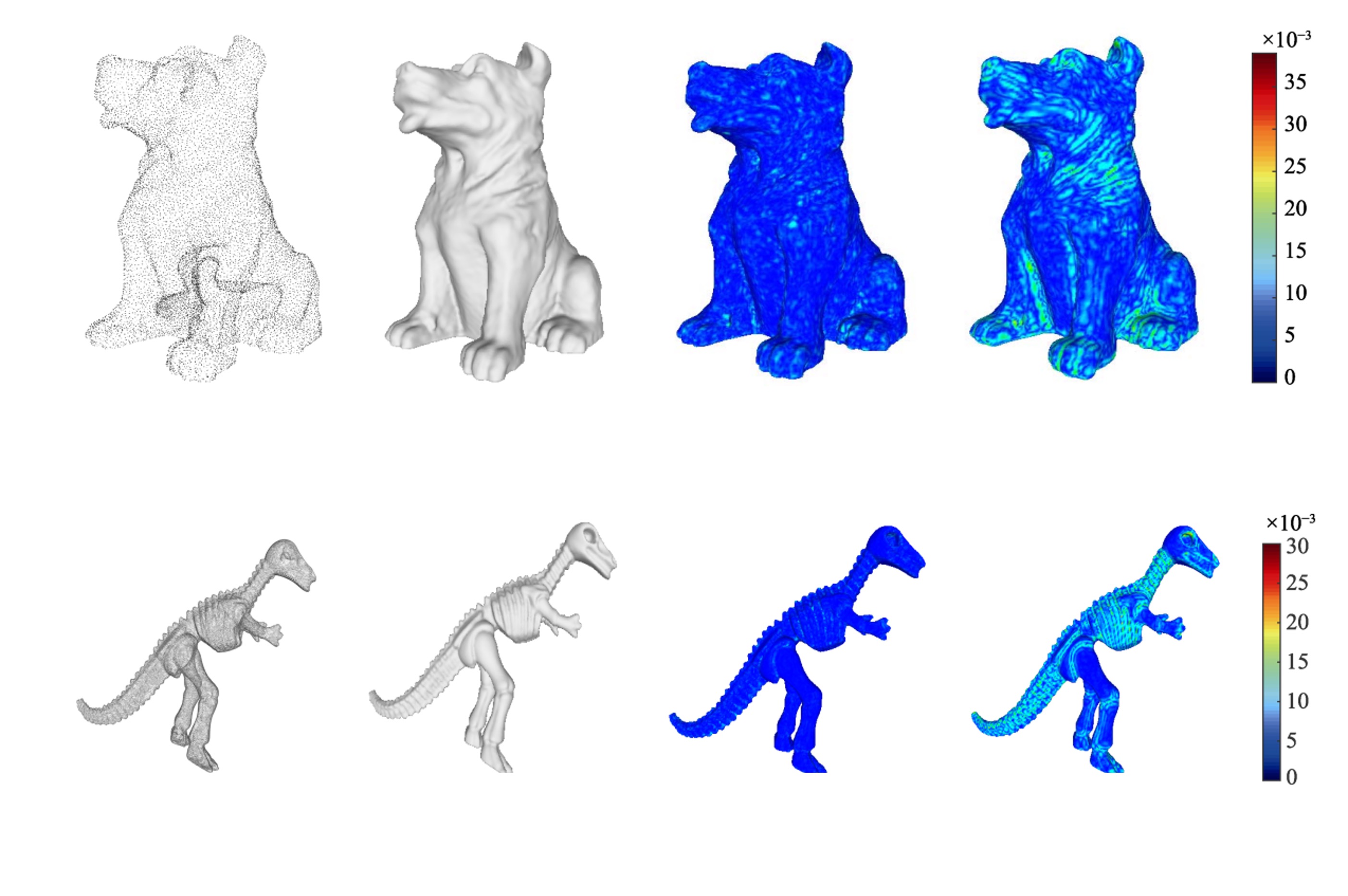

We propose a neural network-based computational framework for the simultaneous optimization of structural topology, curved layers, and path orientations to achieve strong anisotropic strength in fiber-reinforced thermoplastic composites while ensuring manufacturability. Our framework employs three implicit neural fields to represent geometric shape, layer sequence, and fiber orientation. This enables the direct formulation of both design and manufacturability objectives - such as anisotropic strength, structural volume, machine motion control, layer curvature, and layer thickness - into an integrated and differentiable optimization process. By incorporating these objectives as loss functions, the framework ensures that the resultant composites exhibit optimized mechanical strength while remaining its manufacturability for filament-based multi-axis 3D printing across diverse hardware platforms. Physical experiments demonstrate that the composites generated by our co-optimization method can achieve an improvement of up to 33.1% in failure loads compared to composites with sequentially optimized structures and manufacturing sequences.